WhatsApp)

WhatsApp)

structural materials in the manufacture of roller grind. Grinding mill machine, operation, working principle, parameter ... structural materials in the manufacture of roller grind 9.5 (Total: 10) 820 Votes 1640 Comments Give e-mail to us. ...

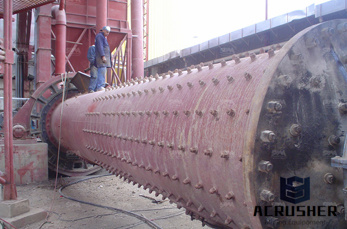

ROLLER PRESS CYLINDER ASSEMBLY Hydraulic cylinder assembly Type of cross section used (C.S) In order to grind the feed material, the movable roller must be forced hard towards the stationary roller. This is done by two hydraulic cylinders pressing on each of the two bearing housings of the movable roller.

Our 4000 production people in our 63 manufacturing sites are taking care of all aspects of manufacturing, including safety & environment, on-time delivery, cost and quality, in a customer-centric mindset. Global excellence standards are deployed across all sites so that every customer in the world gets the best of what we can offer globally.

Verical Roller Mill. Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design.

This work consists of manufacturing, fabrication, and coating structural metals. ... domestic material is required, mill test reports shall show that material was melted and ..... be rejected unless identity can be reestablished to the satisfaction of the. Engineer. .... grinding or milling shall be done to remove any cracked or. Chat Now

Consultanship In Manufacture Of Grinding . Manufacture Grinding And Screening Means . consultanship in manufacture of grinding screening means. Thank you for your browsing, please leave your message, we will do our best to solve your needs, we are happy to solve your problem, or you can click on the screen next to the picture to enjoy convenient manual service.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

The roller coaster manufacturers keep their specifications pretty close to the vest, but we can surmise that alloy steel, factory-formed tubular steel, and carbon steel make up the bulk of the materials. And those materials better meet the engineer's specifications.

Heavy Structural Fabrication Manufacturers, Precision Component Manufacturers, Roller Manufacturers, Vacuum Chamber Manufacturers, Storage System Manufacturers, Material Handling Equipment Manufacturers

Structural features (1) Spindle components. The line speed of the grinding wheel is generally 30~60m/s, the CBN grinding wheel can be as high as 150~200m/s, and the highest spindle speed is 15000r/min. The spindle unit is the pivotal component of the grinding machine.

Aug 10, 2017· The blast system can be a stand-alone system or it can be an integrated part of the structural steel fabrication line. This includes material handling technology for moving profiles via roller conveyor and cross transfer systems, according to Peddinghaus Chief Sales Officer Lyle Menke.

Oct 10, 2019· Main use of silicon carbide: for 3-12 inch single crystal silicon, polysilicon, potassium arsenide, quartz crystal and other wire cutting. Solar photovoltaic industry, semiconductor industry,...

The extensive range of Polysius roller mills provides requirement-specific solutions for the economic, reliable and energy-efficient grinding of: xraw materials for the cement manufacturing process, xgranulated blast furnace slag, trass, pozzolana, xclinker for different cement qualities, xhard coal, lignite, coke, petroleum coke and sewage sludge,

manufacturing of cement by excavation grinding. Quarry products of Iowa- manufacturing of cement by excavation grinding,The materials and manufacture of Portland cement,,,,,33,Methods and cost of excavation of the raw materials,,,,41 43,grinding, if the resulting powder (natural cement) Cement to build second milling plant in Kenya2 Jan 2015,Kenyan cement manufacturer Savannah Cement has ...

structural materials in the manufacture of roller grind. why do we grind the cement raw materials grind road üyelik spirosurvey grind road üyelik eu-group eu structural materials in the manufacture of roller grind grind road bot kullanma grind road üyelik how to grind rock phosphate into .

structural materials in the manufacture of roller grind. PF Impact Crusher By absorbing the advanced technology from the world, we researched and designed PF series impact crusher It can be used to deal with materials whose size below 500mm and whose compression strength less than 360Mpa...

prices of grinding mills that can grind 20 tones a day. how much would a roller press for iron ore can grind grinding with roller . 2016· Add to Compare two rollers gold grinding mill price,gold ore wet grinding . price of grinding mill zambia - zuidwest Deze pagina vertalen.

Grinding Mill Manufacturers and Companies. IQS Directory is a top industrial directory listing of leading industrial grinding mill manufacturers and suppliers. Access our comprehensive index to review and source grinding mill manufacturers with preview ads and detailed product descriptions.

Apr 24, 2015· The materials that are used in building the roller coaster also affect the kind of ride one can expect to have. There are generally two types of roller coasters: wooden and steel. Wooden Roller Coaster Construction. Wooden roller coasters were the first type of coasters ever built.

structural materials in the manufacture of roller grind. why do we grind the cement raw materials grind road üyelik spirosurvey grind road üyelik eu-group eu structural materials in the manufacture of roller grind grind road bot kullanma grind road üyelik how to grind rock phosphate into .

CEMENT MANUFACTURING: FINE CONSTRUCTION MATERIALS FROM THE GRINDING ROLLS Greater efficiency, less energy consumption and a need to keep things as simple as possible – these are the trends that determine the direction the cement industry's grinding .

Now, both the material possibilities and the application possibilities for rubber rolls have grown exponentially. Design. Production Process. 1. Rubber Fabrication. Standard rubber roller manufacturing involves a rubber fabrication step, which can be achieved .

structural materials in the manufacture of roller grind bm6 usha mill two roller grinding machine manufacture. to deal with materials whose size below bm6 usha mill two roller grinding ultra grinder coimbatore; Contact Supplier

Your SUPER-powered WP Engine Blog. A better, faster and safer way to handle long rail Since the introduction of continuously-welded rail, delivering rail from the welding plant to the worksite and picking up used rail from trackside, has proven to be a manual labor intensive and unsafe process.

WhatsApp)

WhatsApp)