WhatsApp)

WhatsApp)

We offer machines and systems, consulting and project support. We are highly specialised on hammer mills. Besides grinding technology we are your competent partner for feeding and transport systems, dedusting and dust explosion protection, processing of substrate for biogas plants, and separation of different materials in food recycling.

Sep 20, 2018· The biogas plant assessed in this study was based on Lansche and Müller . The main characteristics of the plant are summarized in Table 3. The proportions (based on mass) of the biogas substrates were 90% miscanthus silage and 10% liquid cattle manure (Lansche & Müller, 2012). It was assumed that the necessary amount of liquid cattle manure ...

Therefore, for optimum biogas yields, bio-waste grinding machine is required. ... It was observed that the quantity of biogas yield from these substrates increase with increasing percentage ...

Dec 01, 2014· 1. Introduction. Anaerobic digestion (AD) is a process developed at industrial scale for its ability to produce a biogas rich in methane from organic matters frequently considered as wastes (Mata-Alvarez et al., 2000).Among the solid wastes available for AD, agricultural residues are attractive because of the co-production of a digestate rich in nutrients that holds agronomic qualities that ...

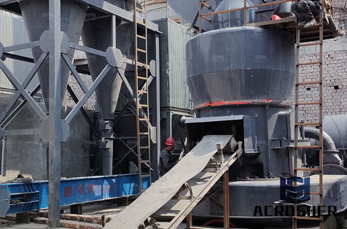

The Biogrinder (type RBG) is used in the processing of biomass for biogas generation. The Biogrinder is in use in southern Germany to crush and mash organic domestic waste. The upstream substrate processing speeds up gas production in the fermenter. Overall, the biogas plant operates more efficiently and reliably.

Crusher Used For Biogas Plants. Stone Crushing Machine: crusher used for biogas plants - We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs.. If you want to learn about our products, please call or write mail consultation.

Therefore, for opti mum biogas productio n, bio-was te grinding machine will be needed for the reduction o f bio-was te sizes. Orhorhoro et al Euro. J. Adv. Engg. Tech., 2017, 4 (7 ): 560-568

Biogas Substate Grinding Machine - Besefinzicht.Nl. Biogas substrate grinding machine kaolin equipment suppliers. biogas plant process grinding machine our shredders process biological and biogenic waste to . get price; pulverizer machine used grinding in biogas plant.

biogas substrate grinding machine. Biogrinder for efficient substrate treatment in biogas. Feb 09, 2013· In biogas plants the Biogrinder of type RBG is designed to process biomass (substrates for example as corn silage, corn straw, manure, grass and others) used for the generation of biogas.

Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

Amazon com Compost Grinder. biogas substate grinding machine manure grinding machine biogas substrate grinding machine Crusher P Performance Optimization of the Växtkraft Biogas 2014· Features of fertilizer crusher machine organic waste crusher machine is the key fertilizer granulation machine widely used in crushing organic compost fertilizer city organic

collected substrate samples and a grinding machine was used to further decrease the sizes of the substrate. According to Orhorhoro et al., (2017C), the finer the particles size, the shorter the hydraulic retention time (HRT). Besides, it leads to an improved biogas yields. Therefore, for an optimum biogas yields, bio-waste grinding

The study was performed in the pilot scale biogas system. The equipment associated with the grinding machine, Conveyor, Added Acid Tank, two-stage anaerobic digesters with built a pillow in each digester for promotion of early up flow and mix aeration, due to the advantage of thermophilic process

A substrate inner/outer edge chamfering machine set for chamfering the outer and inner edges of substrates is shown, and includes inner and outer chamfering machines 11 with grinding wheels for chamfering the inner and outer edges, respectively, of each substrate. A measuring unit 12 successively measures the chamfer length of substrates worked by the inner and outer chamfering machines, .

Apr 24, 2015· Methane output from different substrate 648.5 502.3 423.6 380.3 296.1 242.7 216.2 122.2 0 100 200 300 400 500 600 700 Used Vegtable Oil Ice Cream Cheese Whey Dog Food Corn Silage Raw Manure Meat Pasta Switchgrass ML METHANE PER GRAM TOTAL VOLATILE SOLID ADDED FEEDSTOCK Industry Tip: It is beneficial to have an estimate of the biogas production ...

Feb 07, 2017· But the long and effortful research work seems to have been worth its while, because Tietjen has, in the meantime, patented the new technique for the grinding or crushing ("Prallen") of biogas ...

with the help of hydraulic press machine. The cathode and anode mixtures were milled for 12 h in a cylindrical-capped container with alumina balls as filling with the help of a hor-izontal rotary ball mill and dried in an oven at 150 C. The powders were ground again for 4 h in our in-house-made grinding machine and sieved through a 150 mesh.

The substrates used as raw material for biogas production vary widely by country and based on the type of agriculture practiced there. Even non-typical raw materials such as water hyacinths, empty fruit bunches (EFB), rice straw and whole tropical fruits can be used in a biogas .

useful biogas substrate. The advantage of silage as a substrate for biogas plants is to obtain a relatively large green yield from 1 ha. Not without significance is good susceptibility to ensiling and a large yield of biogas and methane in the anaerobic digestion .

Jul 01, 2020· Biogas from AD is a renewable fuel generated from a variety of organic substrates (feedstocks), and is thus an important technology for both the treatment and recycling of growing solid waste streams. Purified biogas is a drop-in fuel that can replace natural gas, an increasingly important fossil fuel for the global energy supply .

Concrete grinders for coating removal and substrate preparation. Concrete polishing equipment. Propane concrete grinding machines and electric concrete surface profile equipment. We have teamed with Scanmaskin to bring you the best quality concrete grinding machines with increased reliability and long service intervals.

If a substrate is only usable in a biogas plant through decomposition techniques at all, the costs must be added to the price of the substrate, in order to determine the profitability. Hereto on the one hand a realistic estimation of the operation costs of the machine is necessary and on the other hand an equally realistic estimation of the ...

Post sintered ceramics will have uneven peaks and valleys on the surface. The surface roughness needs to be processed by internal and external cylindrical grinding machines, centre-less grinding machines, surface grinder and other ceramic processing equipment. The smaller the Ra value of the surface roughness, the smoother and flatter the ...

Our shredding solutions process biological and biogenic waste to generate an optimal substrate for further utilisation in your biogas plant or in your disposal business. The application area ranges from green or garden waste to food waste and expired goods including packaging to slaughterhouse waste.

WhatsApp)

WhatsApp)