WhatsApp)

WhatsApp)

Aug 14, 2007· The author didn't know how to build a sawmill when he began per se, but learned by doing. ... How to Build a Sawmill for Under $1,000 ... one advantage of having your own mill .

Quite simply, Tom worked tirelessly in pursuit of building the perfect rod. Tom Morgan Rodsmiths evolved from a dream of Tom's while owning the R. L. Winston Rod Company from 1973 to 1991. He always wanted to build a limited number of superior graphite rods for appreciative anglers. Rods not limited by cost or materials.

How to Build a Suppressor By Major Rob Robinette. ... Since I have a Grizzly combo lathe/mill at home that I use for making race car parts I already had everything I needed to make a suppressor. By the way, I have been asked about my lathe/mill but I cannot recommend the Chinese made Grizzly combo lathe/mill because its tolerances are a little ...

May 26, 2017· Subscribe! https://bit.ly/2m1d1y7 T-shirts & Hoodies! https://bit.ly/2kABytm In this tutorial, I'm showing you the simplest way to drill perfectly centered hole in any small rod with simple tools ...

Apr 29, 2019· How to Build a Wind Turbine. A wind turbine is a simple mechanical device similar to the windmill. The blades of your turbine will catch air currents, using that motion to transmit mechanical energy along a drive shaft. This shaft will...

A Miniature Lathe Chuck Part 1 ... "where you are" on your mill table, and the one that I had not got tight had rotated on its own as I was ... It only took about 10 minutes, which is a lot faster than making the tool from a drill rod blank. After I was done, I completely disassembled that chuck on my lathe and cleaned it in solvent. Cleaned the

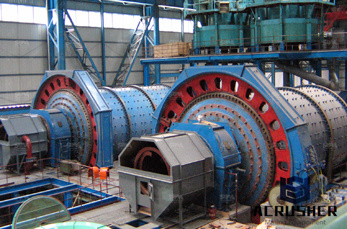

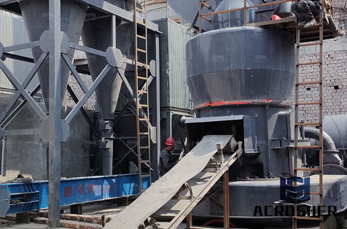

The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding design.He can easily secure a standard Steel Head Rod Mill suited to his particular problem. The successful operation of any grinding unit is largely dependent on the method of .

Home Built CNC Machine Part 1 - Supported Linear Rails: This instructable is part of an on-going project to build a home CNC machine. In this part of the project, I will show you how to build a supported linear rail which can be adapted for the desired length (X-Axis) of your own CNC project. Most ...

Jul 07, 2013· Blade tension is done by a simple threaded rod pushing against the movable side to "where it stops fluttering under load". Enjoy, Mikey ... Am in the process of building me a mill and maybe I should come look at your's. ... My simple homemade bandsaw mill; Share Topic Similar Topics homemade bandsaw mill, help ...

Nov 25, 2014· Working with assistants Scott Goetz and Kevin Braun, a scratch-built block was MIG-welded together out of steel plate and tube sections. Then, Pete continues, "We bought a CNC mill .

How to Make a Mini Milling Machine- Manual or CNC!: I think one of the best things about tools is that they can be used to make more tools! I decided to build a miniature milling machine for machining plastic parts, creating wax patterns and for drilling really small precise holes. I also wanted to...

Portable Sawmills are easy to build. YOU WILL GET A TREMENDOUS SENSE OF PRIDE OUT OF BUILDING A PROCUT PRECISION PORTABLE SAWMILL, PLUS THE ADMIRATION OF THE MANY PEOPLE WHO SEE THE FINISHED MILL. So what are you waiting for?

I made my mill using Bill Rake's pictures on the internet. I did some of my own modifications to the design like to the roller guides, wheels, and acme rod to move the head up and down. If you take your time and make use of a machine shop were needed your saw will cut accurate. I also used 16 hp and would not go smaller.

Jun 29, 2006· Ready for some hard core gadget creation? If you thought your dremel tool was handy before, in today's How-To we'll start building our own CNC machine. Aside from the geek factor, it .

BUILD YOUR OWN CNC MILL. By Julius de Waal. ... So in my design I have substituted them with standard M16 threaded rod. If the engineer feels that he wishes to have finer control/movement, than the M16 threaded rods and nuts can be changed for rods and nuts with similar size UNF thread.

Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit. The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load. Rods in place weigh approximately 400 pounds per cu. ft. .

Lugging a cooler and all of your rods, tackle and tools from your truck down to the water – or, worse, back up to the truck when heading home – is a chore. You can sidestep this entire problem by using a surf fishing cart to help you wheel your gear with ease. It is easy to build your .

Build & Price a Dodge that is tailored to meet your needs. Choose the color, trim, options and more to easily customize your car, SUV or Minivan today.

With a loop of flexible rigging, have your boom hold all of the fiber rod up and over the well safely. Attach the plunger to the fiber rod and start lowering that into the pipe. On the end of the last piece of fiber rod attach the threaded rod, 5/8 to7/16 adapter and hand pump polished rod.

Proof Fly Fishing offers high quality fly rod building supplies at unexpectedly fair prices. blanks, reel seats, Snake Brand Guides, cork, thread, etc...

Aug 15, 2016· In this first video we look at some of the details of the mill and I set the stage for the series I'm doing on building a large cut width bandsaw mill. Plans for this wide cutting bandsaw mill ...

Jan 11, 2012· CRANK AND RODS: 74mm Crankshaft, VW Rod Journals.This is the biggest stroke you can go with, with minimal case machining or other hassles. If you are on a super tight budget, you can re-use the stock connecting rods, but these will require more clearancing of the case than some other rod options, because stock rods tend to be "fatter" on the big end, requiring more room.

InfraBuild is Australia's largest integrated manufacturer and supplier of steel long products and solutions – including hot rolled structural steel, reinforcing bar and mesh, merchant bar, pipe and RHS, rod and wire and building products – enabling the construction of steel-framed buildings, buildings framed in concrete and nation ...

By this drawing, it is suggested that a typical homemade laboratory rod mill or ball mill might be fabricated from 20 cm (8 inch) diameter schedule 40 type 316 stainless steel pipe and would be about 38 cm (15 inches) long. The plans show stainless steel grinding rods for this size of mill may be a graduated charge from 25 to 10 mm diameter (1 inch to 1/2 inch) but variations in size are not ...

WhatsApp)

WhatsApp)